PV Elite®

PV Elite is a complete solution for the quick and intuitive design of new pressure vessels. It also evaluates and re-rates existing vessels, including fitness for service analysis.

What is PV Elite®

PV Elite is a comprehensive engineering application designed for the design, analysis, and evaluation of pressure vessels and heat exchangers. Widely used by engineers in the process, chemical, oil and gas, and power industries to ensure that pressure vessels are safe, reliable, and compliant with various international design codes and standards.

PV Elite provides engineers, designers, estimators, fabricators, and inspectors with solutions that match their pressure vessel and heat exchanger design needs. Because the software is user-friendly, it is perfect for both regular and occasional users requiring fast start-up and confidence in their safety code calculations. PV Elite is a complete solution for the quick and intuitive design of new pressure vessels. It also evaluates and re-rates existing vessels, including fitness for service analysis. The software considers the whole vessel, addressing all the wall thickness rules and stress analysis requirements for vertical towers, horizontal vessels, and heat exchangers. You can also evaluate individual vessel components.

Users benefit from faster workflows thanks to tube sheet design and analysis, rectangular and noncircular vessel analysis, and individual component analysis. PV Elite boosts confidence in your safety code calculations with the software’s design tools and wizards, plus comprehensive error checking to deliver clear, concise, and accurate results.

Overview

Why use PV Elite?

Pressure vessels and heat exchangers are complex equipment, operating under significant pressure and temperatures, carry loads from attached piping, and may contain hazardous fluids. Safety is paramount as the failure of such equipment can be disastrous. Failure of a pressure vessel can cause severe damage to an industrial facility, and potentially lead to loss of life. PV Elite is used to ensure correct calculations are performed, according to recognized international standards, to ensure that the design of a pressure vessel or heat exchanger is safe.

PV Elite is typically used when:

- A vessel containing a fluid is under pressure.

- Other loads could jeopardise the safety of the vessel.

- An insurance certificate is required from a Notified Body

Who uses PV Elite?

PV Elite is used by EPC contractors during detailed design, pressure vessel and heat exchanger OEMs involved in design and manufacturer, and owner operators, to check the remaining operational life of their assets. It is also widely used by Notified Bodies for approving and verifying calculations to provide the necessary certification so the vessel can be put into operation.

Industries Served

Due to the wide variation in design and application of pressure equipment, PV Elite is used in many different industries. PV Elite can help ensure the containment is fit for purpose in any industry where a fluid is stored in a vessel, or wherever heat exchangers are used in cooling or heating processes – such as:

Benefits of PV Elite®

Software internationally recognised by EPCs, Owner operators, and Notified Bodies.

- PV Elite supports a wide range of international codes and standards, ensuring that the designs are compliant with regulations worldwide. Perform analysis in accordance with international code standards - ASME Section VIII Divisions 1 and 2, PD 5500 and EN-13445.

- Perform rapid API579 (Fitness for Service) assessment to evaluate the current state and remaining life of existing vessels.

- Wind and seismic code compliance (such as ASCE, NBC, UBC, IS, etc.)

- Intuitive Modelling Environment: PV Elite offers a user-friendly interface that simplifies the design and analysis process. Its graphical user interface allows for easy navigation, which significantly reduces the learning curve for inexperienced users. Logical design ‘as you go’ workflow makes the software easy to learn and efficient to use.

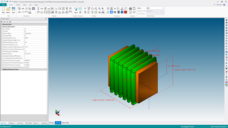

- 3D Visualization: The software provides 3D visualization and easy creation of realistic pressure vessel and heat exchanger models, particularly useful for detecting potential issues early in the design phase, including quick definition of boundary conditions.

- Finite Element Analysis (FEA): PV Elite offers FEA tools, to provide detailed stress analysis of pressure vessel components. This helps in identifying high-stress areas and optimizing designs for better performance.

- Load and Stress Analysis: The software offers comprehensive analysis of loads, stresses, and material behaviour under various conditions, including wind, seismic, and thermal loads.

- Component Design: The ability to design and analyse individual components such as shells, heads, nozzles, saddles, and supports, provides detailed insights into each part of the vessel.

- Rich content: Vessel material definitions, piping and steel component data, local wind-loads, and local seismic loads of many regional markets - are all included.

- Automatic Calculations: PV Elite automates many of the complex calculations required for pressure vessel design, significantly reducing the time engineers need to spend on manual calculations.

- Design Reuse: Engineers can easily reuse existing designs, which speeds up the development process and ensures consistency across projects.

- Customizable Reports: PV Elite generates detailed reports that can be customized to meet the specific needs of a project or client. This includes summaries, detailed analysis results, and compliance documentation.

- Comprehensive Documentation: The software provides detailed documentation of the design process, making it easier to track design decisions and changes over time. Analysis results structured by MAWP and component type making it easy for the user and inspectors to verify the accuracy of equations and calculations output to reports.

- Interoperability: PV Elite can integrate with other Hexagon products, such as CADWorx Plant Professional , and Intergraph Smart 3D, enabling seamless data exchange and workflow efficiency. Bi-directional integration with CADWorx Plant Professional’s Equipment module reduces risk of errors and costly iteration time between equipment design and stress analysis disciplines.

- Includes CodeCalc for quick and efficient design and evaluation of individual components.

- Technical Support: Hexagon provides comprehensive technical support to assist users with troubleshooting, software updates, and best practices, ensuring that teams can fully leverage the software's capabilities. Hexagon regularly updates PV Elite to ensure compliance with the latest codes and standards, as well as to improve functionality and performance.

- Training Resources: Users have access to a variety of training resources, including webinars, tutorials, and documentation, to help them maximize the benefits of PV Elite. Free eLearning available via Hexagon University.

- Widely Used: PV Elite is widely adopted by companies in various industries worldwide, which speaks to its reliability and the trust professionals place in its capabilities.

- Industry Standard: It is recognized as a standard tool for pressure vessel design and analysis, often preferred by engineers for its comprehensive features and ease of use.

PV Elite is a powerful tool for engineers involved in the design and analysis of pressure vessels. Its combination of ease of use, comprehensive code compliance, advanced analysis capabilities, and integration with other engineering tools making it an invaluable tool for ensuring safety, reliability, and efficiency in pressure vessel projects.

Whether designing new vessels or evaluating existing ones, PV Elite offers the features needed to support complex engineering decisions

Capabilities | |

|---|---|

Vessel design and analysis | International seismic analysis |

Exchanger design and analysis | International vessel codes |

Tube sheet design and analysis | Bi-directional integration with CADWorx Plant Professional |

Rectangular and non-circular vessel analysis | Transportation analysis |

Individual component analysis | 3D PDF generation |

Comprehensive error checking | Generation of retirement limits and maximum allowable corrosion allowance |

Saddle, Leg, Lug, Trunnion and Skirt Design | |

Analysis for horizontal shipping of vertical vessels | |

User-definable reports | |

International wind analysis |

Key Features

Customer Success Stories

Unmatched Support

Troubleshoot your PV Elite issues with ease with our dedicated support team and plethora of support documents. Our team provides effective solutions based on extensive product usage and industry expertise.

Expert Training

Empower your team with Hexagon University, which contains our expert training programs as well as tips and tricks for improving your workflows across Hexagon products. Check out live webinars, detailed tutorials and personalized training sessions, ensuring your team is proficient and confident in using PV Elite to its full potential.