Precision You Can Trust. Performance You Can Prove.

A modern, engineering‑grade instrumentation sizing suite built for accuracy, compliance, and efficiency across industrial applications.

What is InstruCalc?

InstruCalc is a comprehensive instrumentation engineering software suite used to size, select, and validate process control equipment such as control valves, flow elements, and relief devices.

With more than 74 integrated engineering programs.

InstruCalc provides technically rigorous, standards‑aligned calculations based on ISA, API, ASME, and ISO methodologies.

It supports multi‑scenario evaluations, produces audit‑ready reports, and equips engineers with tools to avoid operational risks such as cavitation, flashing, excessive noise, incorrect differential pressure, or undersized relief systems.

Overview

InstruCalc 10 represents the newest and most advanced release of the long‑established instrumentation design suite. It is built to modern engineering standards and offers:

- Sizing capabilities for 50+ instrument types

- Control valve sizing for liquid, gas, steam, and two‑phase flow

- Relief device sizing (ASME/API)

- ISO/AGA flow element design

- Waterhammer and pressure‑drop analysis tools

- Real‑time multi‑case (“What‑if”) evaluation

- Robust physical property datasets

- Clean, professional engineering datasheets and reports

The platform is engineered for both design and operational environments, ensuring highly accurate, consistent, and compliant calculations.

Key Features of InstruCalc

- 74+ integrated engineering programs

- Multi‑case what‑if analysis

- Instant graphing & diagnostics

- Standards‑aligned calculations (ISA/API/ASME/ISO)

- Faster modern UI with enhanced performance

- Flexible engineering units (SI/Imperial/mass/volume)

- Import/Export (CSV/Excel)

- Comprehensive physical property database

- Modular tools for valves, flow elements, relief devices & more

- Designed for collaboration & team standardization

Detailed Feature Descriptions:

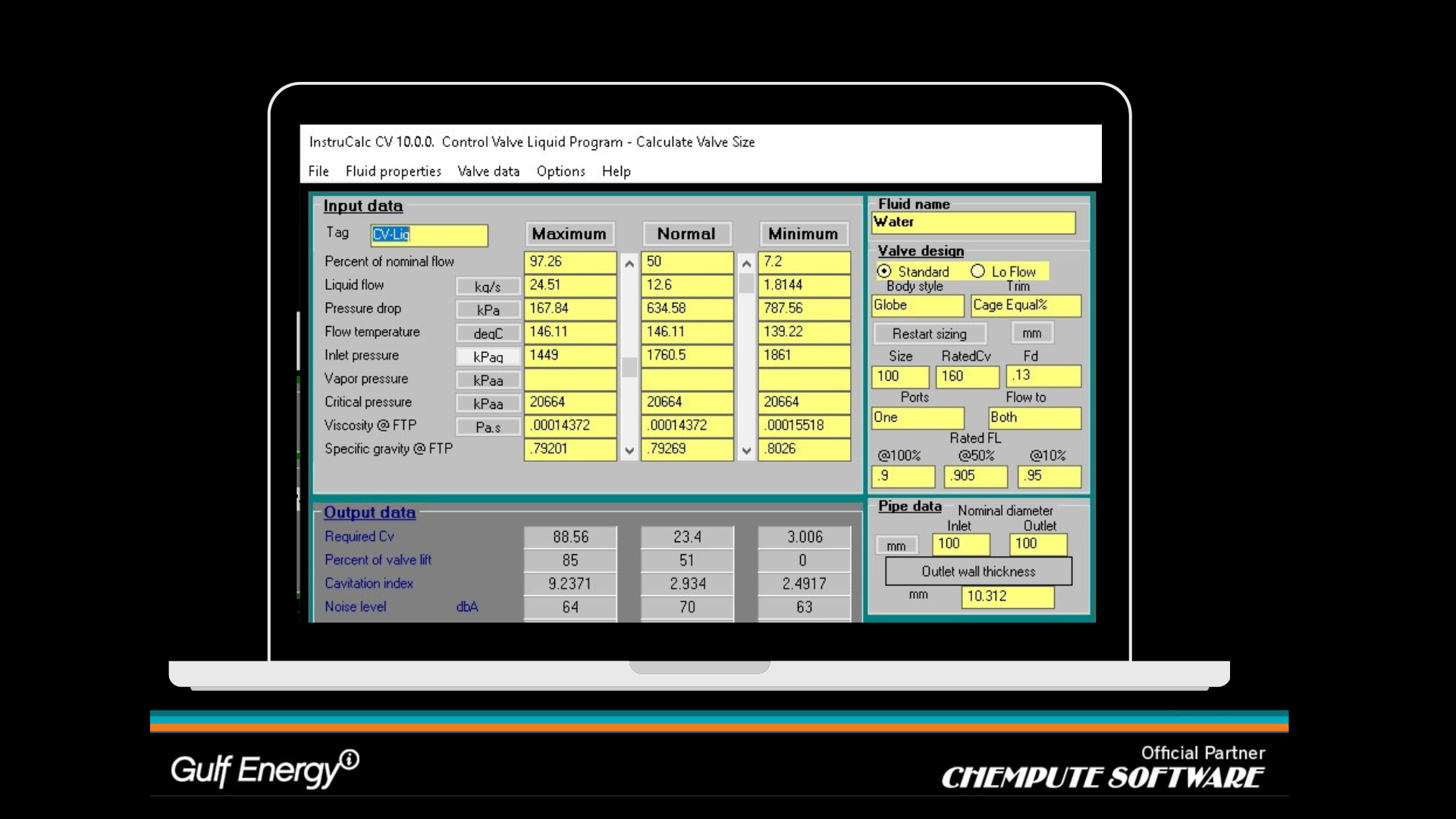

Control Valve Sizing – Liquid, Gas, Steam & Two‑Phase

InstruCalc’s Control Valve module provides full engineering‑grade sizing with diagnostic analysis.

Detailed Feature Descriptions:

Liquid Valve Sizing:

- Allows engineers to evaluate valve performance under maximum, normal, and minimum operating conditions. Provides Cv calculations, cavitation index, noise predictions, flashing likelihood, and piping geometry correction. Output includes required Cv, predicted noise levels, valve capacity, and cavitation checks for safer valve selection.

- Valve Data Selection (Screenshot 7): Engineers can choose valve body style, trim type, port options, and flow direction from an extensive internal valve data library, ensuring accurate performance representation in sizing calculations.Capabilities Include:

- Cavitation & flashing prediction

- ISA 75.17 noise calculations

- Sonic velocity checks

- Rangeability evaluation across multiple flow cases

- Piping correction factors & Fp calculations

- Automatic multi‑scenario evaluation

Fluid & Physical Property Calculations

InstruCalc provides professional‑grade fluid property tools essential for accurate sizing.

Detailed Feature Descriptions:

Liquid Properties Module:

- Calculates density, viscosity, vapor pressure, thermal properties, and bulk modulus across multiple operating conditions (max/normal/min). Supports water, hydrocarbons, refrigerants, and custom fluids.

- Real‑time recalculation as process conditions change

- Multi‑fluid media switching (liquid, gas, steam)

- Integrated engineering property database

- These tools ensure that all sizing programs use high‑integrity fluid property data.

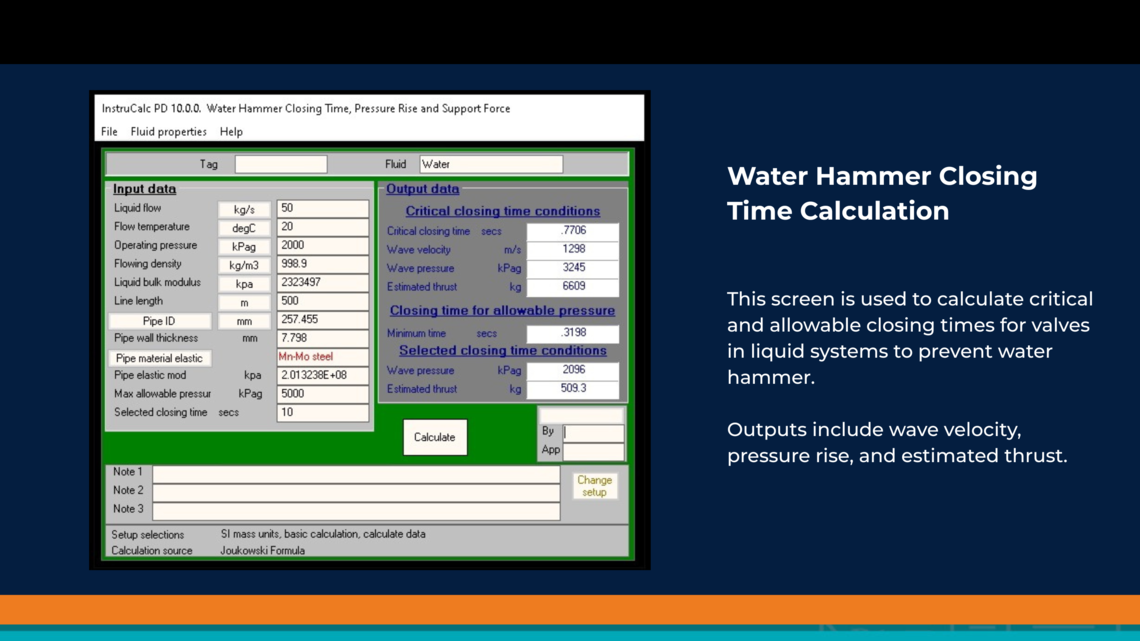

Water Hammer, Pressure Rise & Support Force Analysis

Water hammer can cause catastrophic pipe damage. InstruCalc includes specialized surge analysis tools.

Detailed Feature Descriptions:

Water Hammer Tool:

- Calculates pressure rise based on valve closing time, wave velocity, fluid density, and pipe material. Evaluates thrust forces and provides allowable closing time guidelines.

- Surge pressure rise calculation

- Critical closing‑time determination

- Structural support force estimation

- Joukowsky equation‑based surge modeling

Relief Valve & Rupture Disk Sizing (API/ASME)

InstruCalc’s Relief Valve Suite fully supports API 520/521, ASME Section VIII & NFPA fire case methodologies.

Detailed Feature Descriptions:

Liquid Relief – Known Flow:

- Engineers can select fluid media, enter process conditions, and automatically calculate the required orifice area, relieving capacity, and backpressure corrections.

Relief Program Selector: Includes sizing for:

- Liquid relief (known flow or size)

- Gas relief

- Steam relief

- Two‑phase relief

- Thermal expansion

- External fire exposure — API & NFPA methods

- Rupture disk sizing (gas & liquid)

- Tank venting

Capabilities Include:

- Full API/ASME compliant calculations

- Fire case with API or NFPA heat input

- Built‑in fluid property support

- Relief uncertainty and backpressure evaluation

ISO & AGA Flow Element Sizing

This suite includes comprehensive flow meter and ISO/AGA‑compliant sizing modules.

Detailed Feature Descriptions:

Flow Element Sizing Programs: Includes sizing for:

- Orifice Plates (ISO 5167: corner taps, flange taps, radius taps)

- Venturi meters, Nozzles, and Wedge meters

- Pitot tubes (Annubar)

- Vortex meters

- Rotameters

- Target meters

Restrictions for Cavitating Liquids:

- Special ISO‑based modules for cavitating venturi and thin orifice plate designs.

Capabilities Include:

- β‑ratio calculation

- Differential pressure prediction

- Permanent pressure loss estimation

- Material thickness & flange compliance

- Full AGA 3 & ISO 5167 methodology

Reporting & Engineering Documentation

InstruCalc generates professional‑grade engineering outputs:

- Detailed calculation summaries

- Cv/DP curves, flow graphs, and valve/relief plots

- Datasheets for valves, relief devices, and flow instruments

- Customizable report headers & revision history

Why use InstruCalc?

Who uses InstruCalc?

InstruCalc is used worldwide by:

- Process engineers

- Instrumentation & control engineers

- EPC engineering teams

- Plant design departments

- Reliability & maintenance teams

- Safety engineers (for relief system compliance)

- OEMs and vendors needing accurate sizing data

Industries Served

InstruCalc is trusted across high‑performance industrial sectors, including:

Oil & Gas

Petrochemical & Chemical Processing

Power Generation

Mining & Minerals Processing

Manufacturing & Heavy Industry

Pharmaceutical & Food Processing

Water Treatment & Utilities

Let us tell you about the advantages of InstruCalc

Benefits of Using InstruCalc

Updates and What's New in InstruCalc 10

Engineering Standard Upgrades:

Control Valve Revisions:

- Updated to ANSII/ISA 75.011.01-2012

- Calculation accuracy changed for critical flows

- Viscosity correction factor changed

- Pressure drop calculation revised to agree with Crane Technical paper No 410.

- Option of Cv Units (English) or Kv units (Metric) added.

- Option of either, aerodynamic noise calculation by ISA 75.17 method or InstruCalc method

- Calculation accuracy added (input data within acceptable limits.

Relief Devices:

- Pressure Relief Devices Program follows API 520 Pt 1, 9th edition dated 7/14

Operational Improvements:

- Added the ability to have more than one calculation at a time. Each instance of the program is framed in a different colour. The user can have multiple "what if" scenarios displayed for making engineering decisions.

Chempute Software offers technical support & sales services for InstruCalc

Submit your details and one of our esteemed InstruCalc engineers will contact you soon.

Our offices

Contact one of our departments to talk to us